Unlocking the Potential of Biomass Gasification in the Coconut Industry

Power Your Business, Boost Profits, and Go Green

The coconut industry generates vast amounts of agricultural waste, from husks and shells to leaves and fronds. Traditionally, much of this waste is discarded or burned, contributing to environmental pollution. But what if this waste could be turned into a valuable resource?

Biomass gasification is a technology that converts organic waste into electricity to power operations or sell back to the grid. The process also produces biochar, a byproduct that can enhance soil quality, improve crop yields, and generate additional revenue. Beyond these benefits, biomass gasification helps businesses earn carbon credits and attract environmentally conscious customers.

This blog post explores how biomass gasification works and how it can benefit the coconut industry—financially and environmentally.

How Biomass Gasification Works

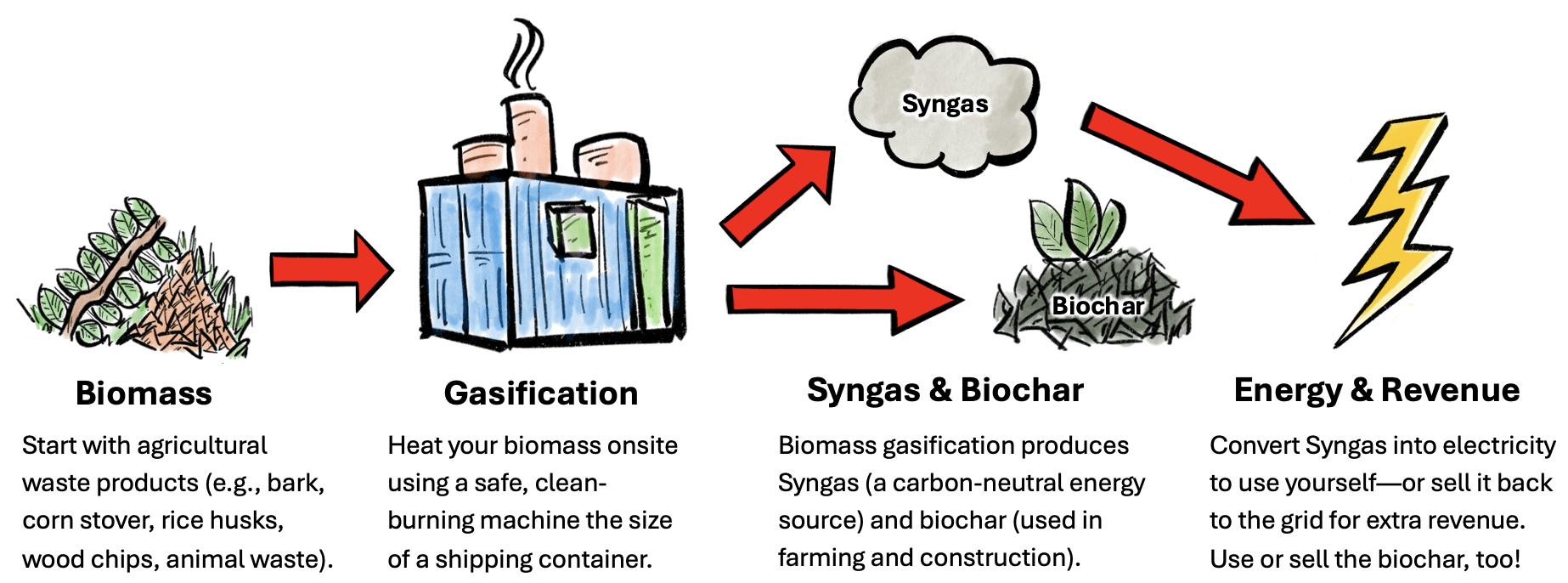

Instead of allowing coconut waste to decompose in landfills or be burned, businesses can use a gasifier to convert this waste into valuable products. The process works as follows:

Organic waste is fed into a gasifier – Coconut husks, shells, and other biomass are placed in a controlled heating environment.

Gasification produces syngas – At high temperatures, in the presence of controlled amounts of oxygen, the biomass is transformed into syngas (a mix of hydrogen, carbon monoxide, carbon dioxide, methane, and nitrogen).

Biochar is created – While syngas is used for energy, the solid byproduct, biochar, sequesters carbon and can be used as a soil enhancer.

Carbon-negative energy is generated – Businesses can use the syngas for heating, electricity generation, or conversion into biofuels.

This process reduces agricultural waste while providing a sustainable energy source, making it a game-changer for the coconut industry.

Benefits for the Coconut Industry

1. Generate Renewable Energy

Coconut processing facilities and farms can use syngas as a clean energy source to power their operations, whether for direct heating or electricity generation, reducing reliance on fossil fuels and lowering operational costs.

2. Create Additional Revenue Streams

Sell surplus energy – Any excess energy can be sold back to the grid, turning waste into profit.

Biochar sales – Biochar is a valuable product in agriculture, improving soil fertility and water retention. Coconut farmers can use it themselves or sell it to other agricultural businesses.

Carbon credits – Companies can earn revenue by selling carbon credits through platforms like Puro, monetizing their sustainability efforts.

3. Reduce Waste and Environmental Impact

Biomass gasification prevents coconut waste from being burned or dumped, reducing pollution and carbon emissions. It also provides a cleaner alternative to fossil fuels, making operations more sustainable.

4. Improve Soil Health and Crop Yields

Applying biochar to soil enhances its ability to retain nutrients and moisture, reducing the need for chemical fertilizers and irrigation. This leads to healthier coconut palms and increased productivity.

5. Access Government Incentives

Many governments offer financial incentives for companies that adopt green technologies. Additionally, compliance with sustainability standards can open new export opportunities, particularly in environmentally regulated markets like the European Union.

6. Strengthen Brand Reputation

Consumers and businesses increasingly prefer to work with eco-friendly companies. By implementing biomass gasification, coconut businesses can improve their market positioning and attract sustainability-conscious customers.

Why Now Is the Right Time

The biomass gasification market is expanding rapidly. With global concerns about climate change and rising energy costs, the demand for sustainable energy solutions is growing. Investing in this technology today can position coconut businesses ahead of the curve.

Carbon2H Biomass Gasifiers

At Carbon2H, we manufacture cutting-edge biomass gasification systems designed for industries like coconut processing. Our CE-certified gasifiers meet the highest safety and efficiency standards and can be customized to handle different production scales, from 30 kW to 500 kW systems. Learn more about our product portfolio here.

Our solutions allow businesses to convert coconut waste into renewable energy, improve sustainability, and boost profitability.

Ready to Get Started?

If you’re interested in integrating biomass gasification into your coconut business, we’d love to help! Contact us today to explore how Carbon2H gasifiers can enhance your operations while supporting sustainability efforts.