How Biomass Gasification Can Help Your Company Boost Earnings

Most entrepreneurs think implementing green practices in their business means higher costs and lower profits. But this is certainly not the case. Biomass gasification can help companies in agriculture, forestry, and other sectors boost their profits and maximize savings.

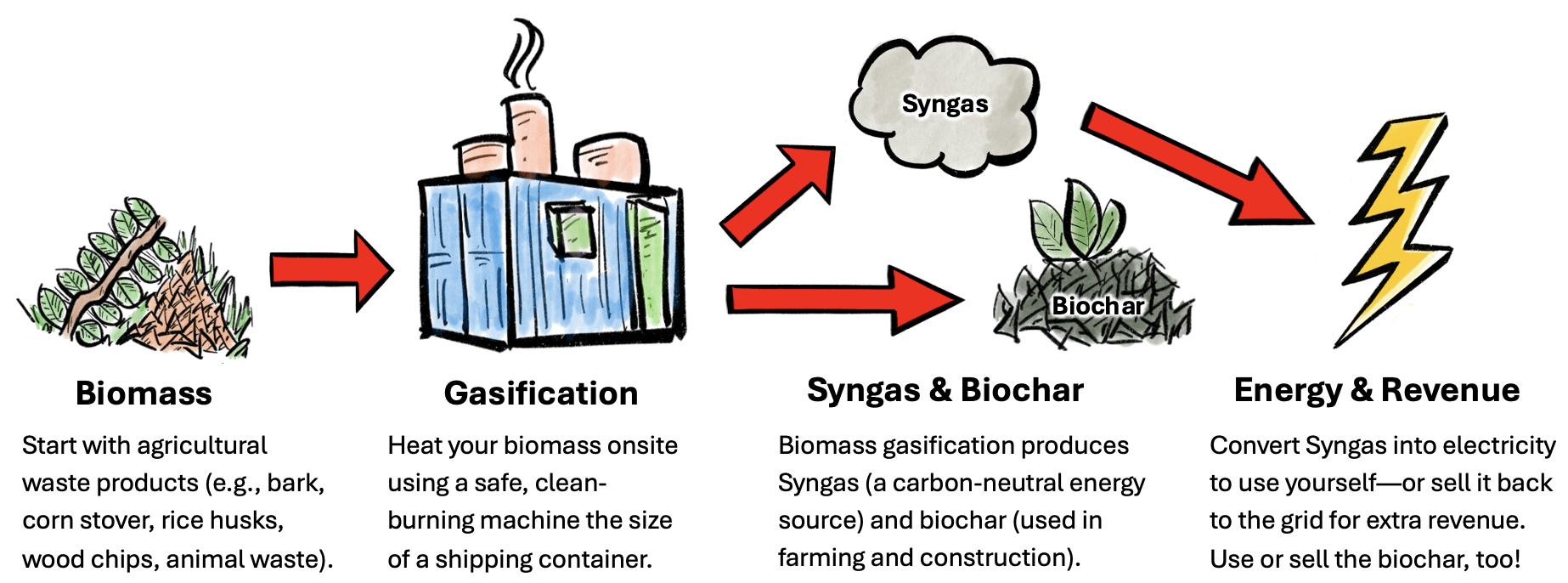

If you've never heard of 'biomass gasification', let us briefly explain what this process is and how it works. Industries tend to produce tons of so-called organic waste, also known as biomass. Some common examples include wood chips, bark, animal waste, and more. One option is to turn these materials into gas by applying heat and pressure in a controlled environment without combustion. This gas can then be used to produce clean energy, which can be sold to other industries or used by the company itself to cut down energy costs.

Biomass gasification is considered a green practice, as compared to the usual combustion organic waste goes through, it produces way less CO₂ emissions. This procedure is also a greener option for companies that do not burn their organic waste but tend to leave it to rot. Why? When these materials, for instance, wood, are decomposed by microorganisms in our soil, they release all the CO₂ trapped inside them over long periods. Biomass gasification, on the other hand, can be used to produce biochar, a material used as a fertilizer that can trap CO₂ for hundreds and sometimes even thousands of years.

But how can biomass gasification help your business increase earnings and boost savings? Let's start with the former.

How Can Biomass Gasification Boost Your Earnings

Companies opting for biomass gasification can multiply their revenue streams. This process can help industries make extra money by producing clean energy, biochar, and carbon credits that can then be sold to other companies. Let's examine each of these in detail.

Renewable Energy Production

One of the main revenue streams of biomass gasification is producing and selling renewable energy. Let's look at some numbers to understand how much energy you could produce using this technology.

Using our 500kW gasification plant as an example, the system processes approximately 750kg of woodchips per hour, converting it into 500kWh of electricity. With energy prices in Germany averaging €0.17 per kWh for small industries, this translates to a revenue of €85 per hour.

Assuming 20 operational hours per day, the plant generates €1,700 daily, highlighting the significant potential of gasification as a revenue source.

Biochar Sales

We already mentioned biochar, but let's discuss it in more detail. This material produced through biomass gasification can capture CO₂ for centuries. Biochar is a highly absorbent material often used by farmers to improve soil health, limit methane emissions, and even reduce water usage (Ghazouan, 2023).

In addition to energy production, the plant creates biochar as a valuable byproduct. Producing approximately 188kg of biochar per hour, the 500kW plant from our example above, yields 3.76 tons of biochar daily. With the average biochar price at $131 per ton in 2023 (Cloverly, 2024), this adds $492 per day in potential revenue.

The potential of this so-called 'black gold' is testified by the fact that massive corporations such as Microsoft, JP Morgan Chase, and Shopify are now investing in it (Reuters, 2022). Do you need more data? The biochar industry was valued at $600 million in 2023 and is projected to grow to nearly 2.5$ billion by 2025!

Carbon Credits

Let's start with the basics. Carbon credits - also known as carbon certificates, carbon offsets, and more - are non-physical products that can be great allies in our fight against climate change. These represent the avoidance, reduction, or sequestration of one ton of CO₂e (with the final 'e' standing for all types of greenhouse gases emitted, not only carbon dioxide) from the atmosphere.

Companies can produce so-called carbon credits to then sell to other businesses to meet all the necessary environmental requirements by law while ideally continuing to work towards implementing greener practices. Carbon credits are classified based on quality, with prices going from a few euros to several hundred per ton of CO₂e removed from the environment. Specific criteria must be met for carbon credits to be considered high quality. Some of these include (Harvard Business Review, 2023):

Additionality: The CO₂e emission reductions should be additional. In other words, they would not have occurred without carbon credits revenues.

Permanence: The CO₂e removal is long-term, with some setting the standard at 100 years and others raising the bar to 1,000 years.

Reliable quantification: The CO₂e reduction, removal, or avoidance must be rigorously quantified.

No double-counting: Carbon credits should be claimed by only one entity.

Both biomass gasification credits and biochar credits have the potential to be of high quality and, therefore, to be sold at high prices, creating an extra revenue stream for your business.

In addition to energy and biochar production, the biomass gasification plants also generate revenue from carbon credits. With approximately 2.68 tons of CO₂e embodied per ton of biochar (Fawzy et al, 2022), the 500kW plant sequesters 10 tons of CO₂e daily. At the current EU carbon offset price of € 80 per ton, this adds €40.3 per hour or €806 per day in potential revenue.

How Can Biomass Gasification Help Your Business Maximise Savings

Implementing biomass gasification in your business will not only boost your earnings but also help you maximize your savings.

Syngas

Biomass gasification turns biological waste into a gas containing hydrogen, carbon monoxide, carbon dioxide, methane, and nitrogen. Known as syngas, this product can be used to generate electricity to fuel all your machinery. Alternatively, syngas can produce biofuels and chemicals, such as methanol, ethanol, synthetic diesel, and ammonia. Syngas can also lead to the production of hydrogen, which can be used to generate clean energy (Britannica). In other words, you will drastically reduce your energy bills if you decide to use the clean energy produced thanks to biomass gasification for the direct benefit of your business!

Fire Risk Reduction

Another factor worth mentioning is that biomass gasification decreases the risk of fire, which is particularly crucial for the forestry industry. People working in this industry are well aware of how much economic damage a fire can cause, destroying years of hard work in just a few seconds!

Today, most forest residue harvesting for industrial purposes only focuses on dead-standing trees, leaving most organic material on the ground. This increases fire hazard while also contributing to the fast spread of blazes. Biomass gasification, on the other hand, uses organic waste, such as dry leaves or broken branches, all highly flammable materials, and removes them from the environment, therefore decreasing the risk of fires.

Greener Policies Equal More Clients

In 2024, going green is no longer only a moral obligation of all companies but also a great way to boost earnings. Plenty of published research and studies show how implementing effective, sustainable practices attracts more buyers, as more and more people are now giving extreme importance to the sustainability policies of the brands they choose to work with.

According to an article by Forbes, in 2017, roughly 87% of consumers declared having a more positive opinion of companies supporting social and environmental issues. The same percentage also reported being willing to buy a product with a social or environmental benefit (Forbes, 2018).

Eager To Try Biomass Gasification?

If you are eager to multiply your revenue streams, boost your earnings, limit your expenses by producing your own energy, and make your business greener, don't hesitate to contact us. You can do so by either emailing us at sales@carbon2h.com or filling out our contact form.